top of page

Who We Are

GD Casting Group was formed through the merger of Dart Casting and General Die Casters—two legacy leaders in aluminum high-pressure die casting.

With combined roots dating back to 1957, we’ve built a powerhouse in U.S. manufacturing, offering end-to-end solutions from tooling design to final assembly. Our broad industry experience and deep technical know-how make us the go-to partner for complex, precision aluminum components.

With over 30 die casting cells and 25 CNC machines, we offer full-service capabilities from casting to assembly—delivering where others can’t.

High-Performance Tooling. Proven Results.

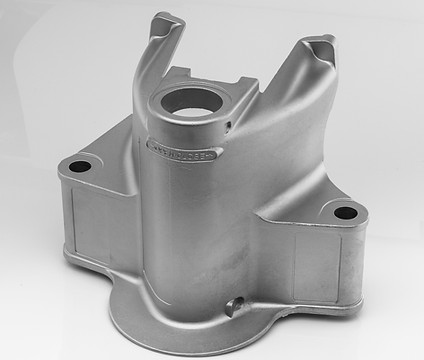

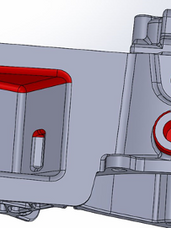

Our expert die cast engineers use MAGMA flow simulation to design precision tools that consistently produce compliant parts—shot after shot.

With optimized gating, cooling, and venting, our tools outperform and outlast the competition, protecting your investment and your production schedule.

With longer tool life, faster cycle times, and fewer casting issues, GD Casting delivers the performance—and ROI—that buyers expect.

What started as a single- die machine shop in Illinois and a quality-driven operation in Ohio has now become one unified team—built to solve complex die casting challenges with precision, speed, and dedication.

With over 30 die casting cells and 25 CNC machines, we offer full-service capabilities from casting to assembly—delivering where others can’t.

ISO 9001:2015 Certified Across Both Facilities

From first shot to final shipment, our ISO 9001:2015 certification guarantees the process controls and traceability your industry demands.

With robust APQP practices, DFM collaboration, and full PPAP documentation — your critical tolerances and specs stay locked in from run to run.

High Capacity.

Smart Standardization.

Lower Costs.

With 35+ aluminum die cast machines and 25+ CNC machining centers across our two facilities, we’re built for volume and speed.

By standardizing our equipment across locations, we streamline training, reduce downtime, simplify maintenance, and share spare parts—all of which drive real efficiency. And for you, that efficiency shows up where it matters most: in consistent quality, faster lead times, and lower piece prices.

Industries Served

From home essentials to industrial innovations, our expertise in die casting spans diverse industries.

Explore the latest in aluminum die casting—from engineering tips and alloy insights to industry trends, project and employee spotlights. Our articles are designed to help engineers, buyers, and innovators turn prints and models into high-quality castings.

bottom of page